Roll Crusher

Contact Now

Products Details

Description

Roller crusher is suitable for industries such as coal, metallurgy, mining, chemical, and building materials, and is more suitable for crushing raw coal (including gangue) in large coal mines or coal preparation plants.

Features

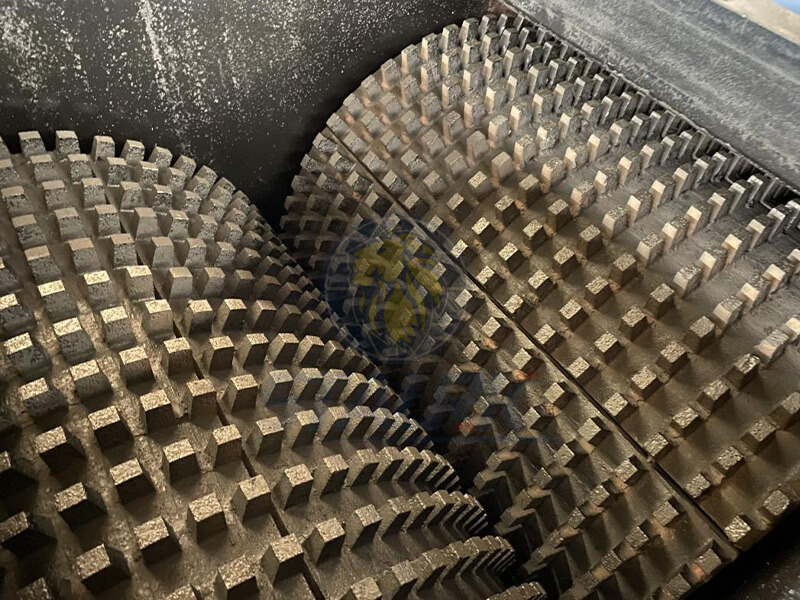

1.Dual Roller Design: Two counter-rotating rollers crush materials efficiently through compression and shear forces.

2.Adjustable Gap: The roller gap can be adjusted to control output size for coarse or fine crushing.

3.Handles Sticky/Wet Materials: Processes sticky or wet materials without clogging, ideal for tough conditions.

4.Durable & Low Maintenance: Wear-resistant design with fewer moving parts reduces maintenance and operational costs.

Advantages

1.Uniform Particle Size: Dual rollers ensure even crushing, producing consistent output for precise sizing in industries like mining and cement.

2.Energy Efficient: Low-speed compression reduces energy use, lowering costs and environmental impact in large-scale operations.

3.Compact Design: Simple, space-saving structure allows easy integration into existing lines and suits facilities with limited space.

4.Versatile Material Handling: Processes hard, soft, brittle, and sticky materials, making it ideal for mining, cement, and chemical industries.

Working Principle

The material is crushed by a pair of counter-rotating rollers. Material is fed into the gap between the two rollers from the top feed port and is gradually crushed as it is drawn into the gap by friction. The finished product falls out from the bottom. When encountering overly hard or unbreakable material, the rollers automatically retreat, increasing the gap to allow the hard material to fall through. With the help of hydraulic cylinders or springs, the rollers return to their original gap, protecting the machine. By adjusting the gap between the two rollers, the maximum particle size of the product can be controlled.

Application

Roll crusher is suitable for medium-hardness materials such as limestone, slag, coke, and coal in industries including cement, chemical, power, metallurgy, building materials, and refractory materials. It is used for intermediate and fine crushing operations.

Technical Parameters

Model | Max Feed Size (mm) | Capacity (t/h) | Power (kW) | Weight (t) | Roller Diameter (mm) | Application |

2PG400x250 | 25 | 5-10 | 11 | 1.5 | 400 | Fine crushing of coal, limestone, etc. |

2PG610x400 | 40 | 10-20 | 22 | 4.5 | 610 | Medium crushing of ores, slag, etc. |

2PG750x500 | 50 | 20-40 | 37 | 7.5 | 750 | Medium to fine crushing of brittle materials |

2PG1000x700 | 70 | 40-80 | 55 | 12 | 1000 | High-capacity crushing of coal, coke, etc. |

2PG1200x800 | 80 | 60-120 | 75 | 18 | 1200 | Large-scale crushing of hard and brittle materials |

2PG1500x800 | 100 | 100-200 | 110 | 25 | 1500 | Heavy-duty crushing for mining and industrial applications |

4PG900x700 | 60 | 30-60 | 45 | 15 | 900 | Fine crushing of coal, limestone, and brittle materials |

4PG1200x800 | 80 | 80-150 | 90 | 22 | 1200 | Medium to fine crushing of ores, slag, and industrial materials |

4PG1500x1000 | 100 | 150-300 | 160 | 35 | 1500 | High-capacity crushing for mining and heavy industrial applications |